15th Aug 2024

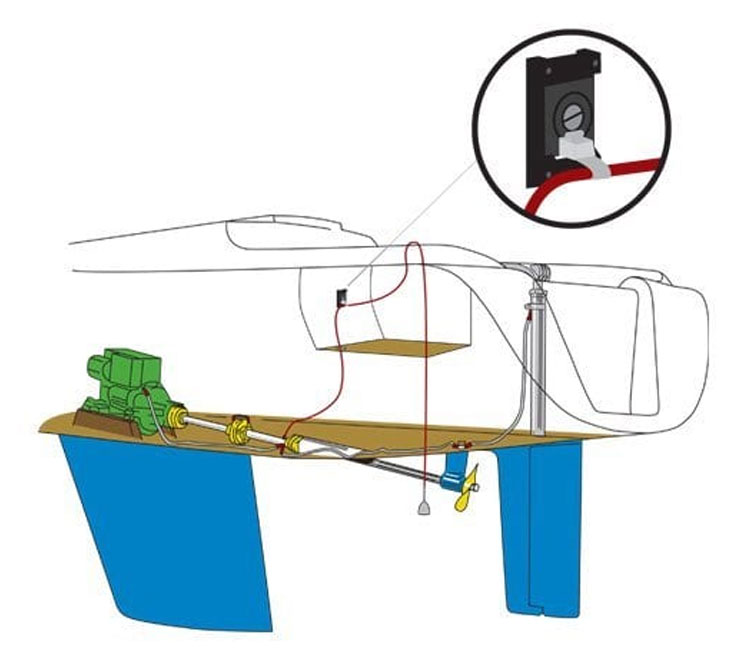

This article covers fitting hanging anodes. Hanging anodes are an alternative method to hull mounted anodes and will provide the same cathodic protection for all types of water craft whether GRP, steel or wood. Most leisure craft are constructed of GRP and the following information is based on this type of vessel. Hanging anodes can also be used on static marine structures. Hanging anodes can be used to protect sail drives, sterndrives and even outboards. The anode is hung over the side of the craft at the stern and the cable is connected inside the vessel to provide continuity to the underwater items to be protected. Hanging anodes can also be useful for environments where you want to provide additional anodes to help take the strain on the fixed types.

Traditional hanging anodes have the wire cast into the anode material and once consumed the whole system has to be disposed of. The benefit of this is that you can be sure the anode will not fall off if it has not been secured correctly and is isolated with a layer of resin. However the MGDuff version features an interchangeable anode system allowing the replacement of the anode material without disturbing the bonding system which can be very handy. This is particularly useful when a craft is moored in differing water types as the system allows the correct anode material to be selected whilst only using one hanging cable. It can also be used to back up existing anode systems. Another advantage is the anode can be checked by simply lifting the anode out of the water and visually inspecting it for wear.

Hanging anodes are only to be used when the vessel is moored. When under way, coil the cable and secure as you would for any line. Never start an engine with a hanging anode deployed, the anode may be drawn into the propeller and cause damage.

Hanging Anode Fitting Guidelines:

- Identify a suitable location on the engine or gearbox to fix the M10 terminal. For saildrives, connect to the mounting bolts or sterndrives to the transom shields. The engine may already have bonding cables attached for existing hull mounted anodes. If so, attach to the same point.

- If the boat has a flexible coupling ensure that the coupling is bridged to ensure continuity

- Run the cable back from the connecting terminal into a suitable storage locker that can stow the hanging anode and cable when the vessel is underway

- Find a suitable place on a bulk head to fix the supplied cable mount or hook. Either screw or bolt the mount into place

- Using the supplied hook or cable tie, secure the cable in a position, so the cable is not under stress

- Run the rest of the anode cable out of the locker and to the stern of the boat

- Ensure you have the correct anode material for the water type the boat is moored in

- Remember – ZINC for SALT WATER, ALUMINIUM for BRACKISH WATER, and MAGNESIUM for FRESH WATER.

- Secure the anode to the cable by screwing the anode into the female connector. Ensure the anode cable connection is tight by tightening the nut on the anode thread onto the female connector

- Hang the anode over the stern of the boat at a height level with the propeller

- Coil any leftover cable in the locker and secure away for travel

- With a good quality multi meter check that there is continuity between the anode and prop shaft

- If possible, measure the resistance and ensure a reading of less than 0.5 Ohms is achieved.