16th Aug 2024

These instructions are for fitting anodes to aluminium hulls in or salt or brackish water only.

- Prepare and paint the hull in accordance with a reputable paint manufacturer's specification before anodes are fixed.

- The propeller shaft can be fitted with an electro-eliminator brush and earthed to the hull.

- The gearbox should be bonded to the hull using 4mm² multi-stranded cable and any flexible couplings in the shaft should be bridged with a copper strap or cable

- When fitting and replacing bolt-on anodes, always ensure that the serrated fan disc washers are replaced.

- Do not paint the surface of the sacrificial anode.

- Check the cathodic protection of your boat by measuring the voltage with a multmeter

- Zinc or aluminium anodes can both be fitted to aluminium hulls in salt water

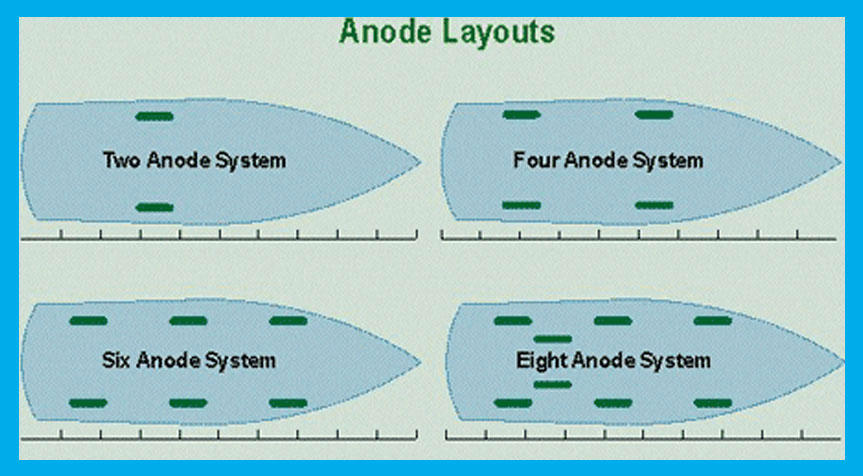

Positioning the anodes

- The anodes should be positioned on the outside of the hull, below the waterline, in a similar way to that of steel hulled craft.

Maintenance

To ensure an optimum level of protection, anodes should be replaced when 60% consumed or if it is anticipated that they will go beyond this level of corrosion before the next scheduled docking.

Zinc hull anodes

Low-profile cast 00274E zinc hull anodes are suitable for lower-speed craft on which the surface mounting will not result in excessive drag. These anodes can be attached after construction. Diagram shows the ZD72BMLP by MG Duff.

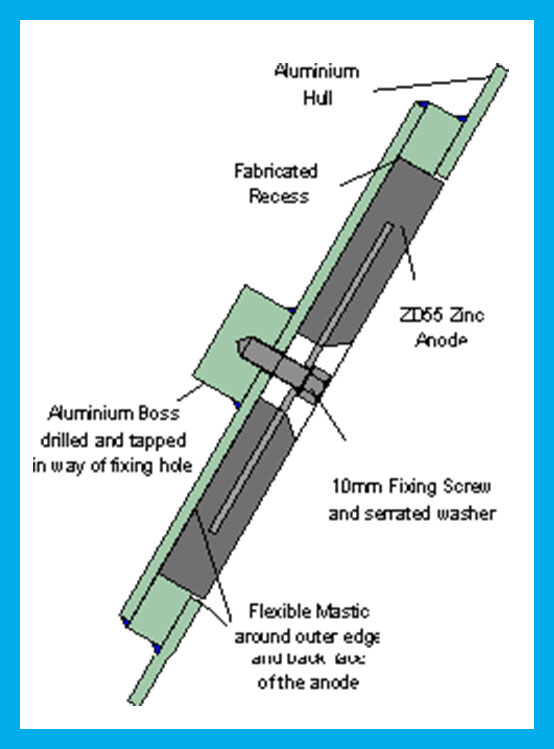

Hull-mounted recessed disc anodes

225mm diameter hull-mounted recessed disc anodes or Tecnoseal 00156 are generally used for flush mounting when minimum drag is required. Hence, the anode is normally incorporated during the construction process. Diagram shows equivalent ZD55.

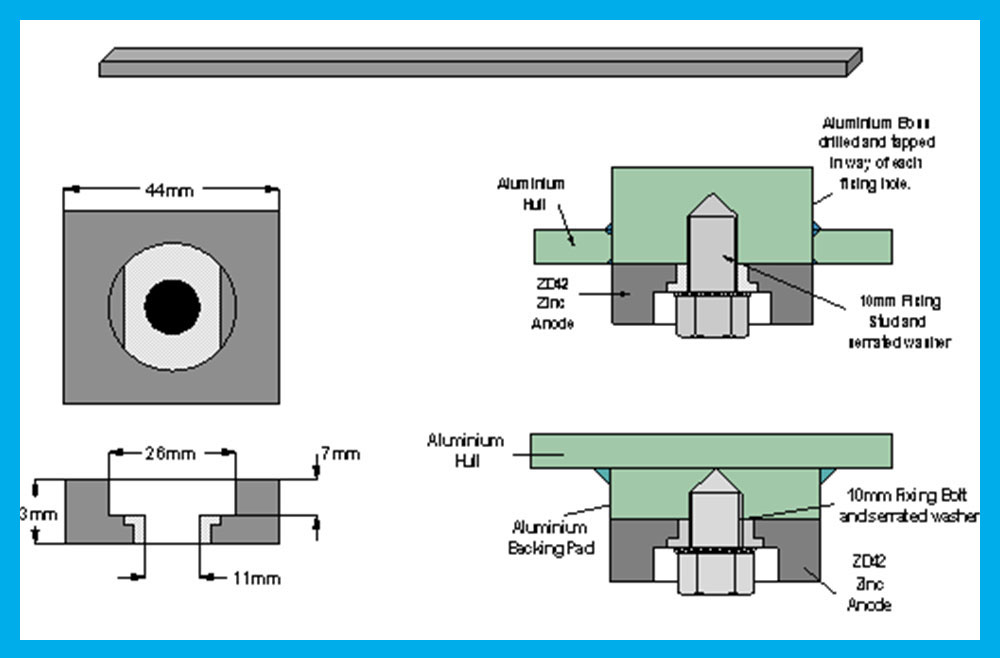

Zinc strip anodes

- ZD42 strip anodes are low-profile zinc anodes with non-reactive aluminium inserts and are ideally suited for fitting to high-speed aluminium-hulled boats. The anodes are not recessed, but are prominent on the surface of the hull and can be attached after construction.

- Each type of ZD42 strip anode requires three or more fixing positions. The ZD42/26 and ZD42/54 anodes need three fixing positions, while the ZD42/72 requires five fixing positions on standard boats, rising to seven on fast craft.

- ZD42 anodes are supplied in 1830mm lengths and can be cut to length. They can be supplied un-drilled or drilled and counter-bored to standard centres. Fixing holes are drilled to suit 10mm studs and it is imperative that the fixing hole is counter bored down to the aluminium cor

Key instructions for fresh water only

Due to the difference in water type and aluminium hull, it is not possible to use magnesium anodes in this situation as it causes Hydrogen Embrittlement. Corrosion in fresh water is at a rate of approximately 5 times less than in salt water which means that a good coating of paint will help prevent corrosion.

Stainless Steel Prop Shafts Or Rudder

Magnesium anodes can be fitted to propeller shafts and rudders in fresh water, as long as care is taken to ensure the anodes are not touching the aluminium hull.