3rd Oct 2024

Top Tips For Fitting Anodes To Hulls

- The anodes should be positioned on the outside of the hull, below the waterline.

- There should be nothing obscuring the anodes from the parts to be protected.

- The fixing studs must be located above the bilges.

- The anodes must be located so as to ensure the minimum run of bonding cable to the parts to be protected.

- There must be reasonable internal access to the fixing studs.

- The anodes should not be positioned in front of or in line with echo-sounding transducers or log impellers.

- The surface of the sacrificial anode should not be painted.

- Use backing pads on wooden and GRP hulls so buy as a kit rather than anode only

How To Fit Sacrificial Anodes To Hulls

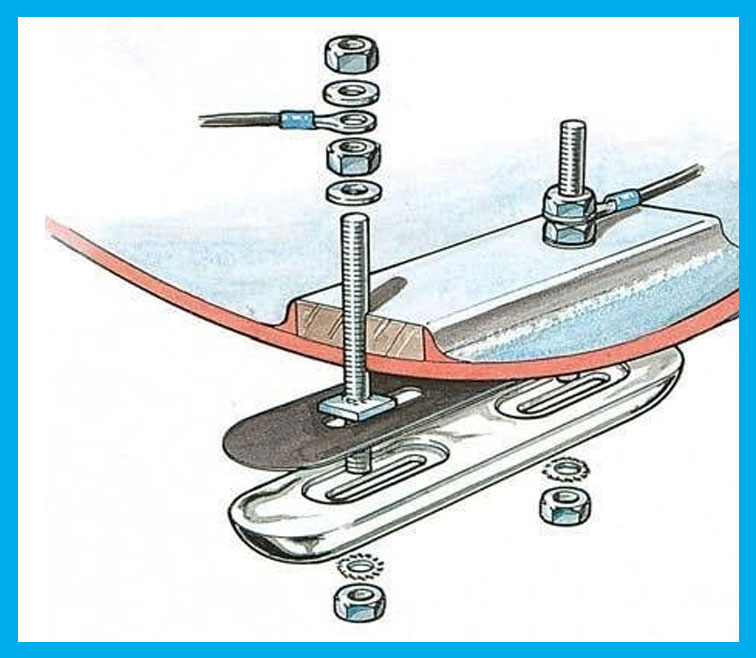

- If necessary, reinforce the inside of the hull where the anode is to be fitted.

- Drill holes to take the fixing studs at the appropriate points.

- On wooden-hulled boats, fixing studs should be sleeved or painted to insulate them from the surrounding timber. If you choose to sleeve the studs, use either a heat-shrink tube or ensure that the inside of the sleeve is packed with a suitable marine-grade sealant.

- Before inserting and securing each fixing stud, apply a generous amount of marine-grade sealant to the shank and collar where the stud touches the hull to ensure a lasting seal.

- Whenever an anode is fitted to a GRP or wooden hull, an anode backing sheet must be used to control the wastage of the anode and to protect the hull. The anode backing sheet should be replaced with every new anode.

- When attaching anodes, always ensure that fan disc washers are fitted under the securing nuts. The washers help to assure the contact between the anode and the cathodic protection system. The fan disc washers and nuts should be replaced each time the anode is replaced.

- Protect the fixing studs on assembly with paint or grease inside and outside the vessel.

Bonding The Cathodic Protection System

- Use 4mm² or larger PVC-insulated multi-stranded copper cable.

- Ensure that all connections are clean and tight.

- The best way to bond the anode to the propeller shaft, gearbox or engine casing is by using an electro eliminator.

- Insulated flexible couplings should be bridged by a short length of bonding cable or a copper strap to carry through the contact between anode and propeller.

- Bronze and stainless steel rudders, rudder hangings and shaft brackets should also be bonded to the main anodes.

- Trim tabs should be protected with separate anodes.

- Steel rudders must be protected with separate anodes.

- Do not fit the same anode to ferrous and non-ferrous metals.

- Timber-hulled boats may be prone to electro-chemical decay and so particular care must be taken with this type of hull

Different Anodes For Different Water Types

As a rule of thumb, you should only use 1 type of alloy across all your anodes unless specifically given professional advice to the contrary. Use zinc or aluminium for salt water, aluminium for brackish water and magnesium for fresh water.

Different Styles Of Bolt On Hull Anodes

Hull anodes for these types of vessel are typically bolt on style. They can be found in various shapes and sizes to suit your protection requirements. You should always check your overall voltage of the anode configuration with a multimeter to ensure you don’t over or under protect your vessel. Here are some of the most common types found on boats in the UK and Europe.

Euro Style Anodes

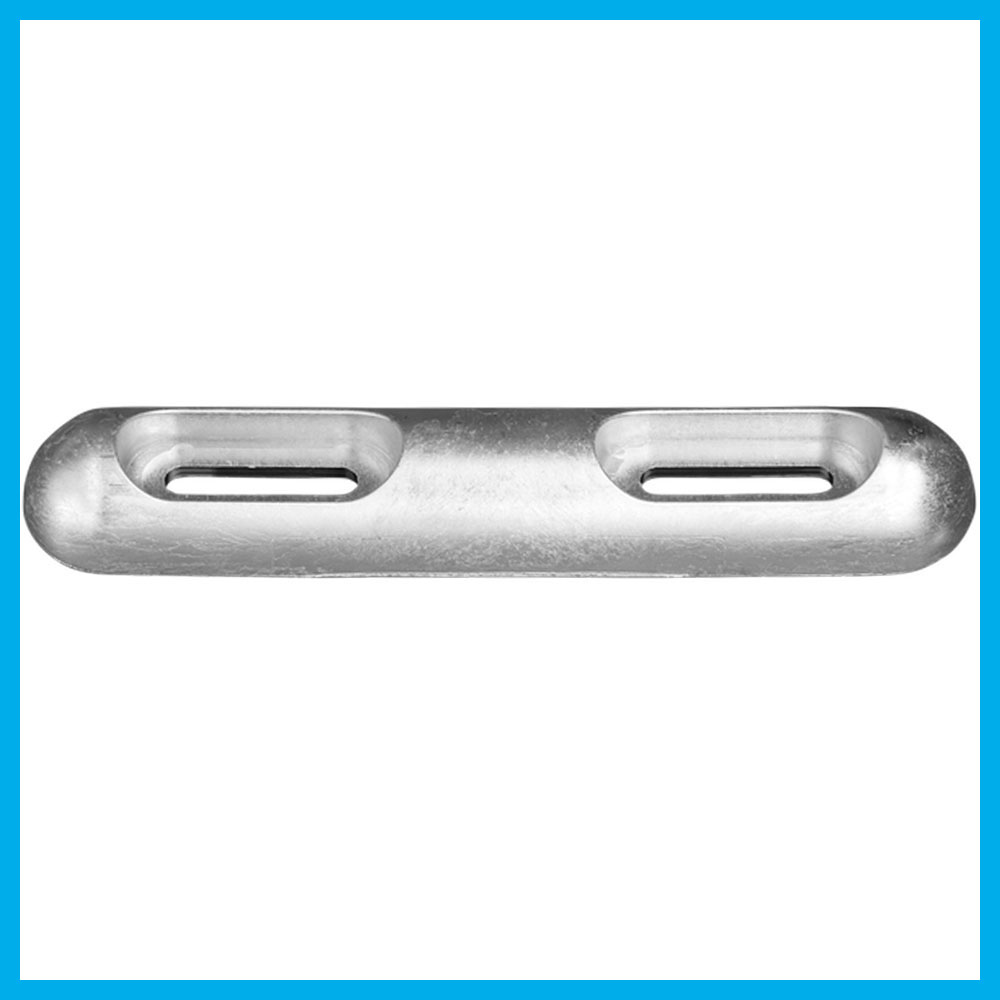

The Euro style anodes are available in all 3 alloys and in the small mini euro and large euro shapes. This type has the advantage of having a plate through the centre with a long opening for easier fit and manoeuvring of bolts to fit. Often used on Fairline boats amongst others. Backing pads available for both sizes.

Scandinavian Style

The Scandinavian style anodes are typically available in zinc for salt water and are traditional ingot shaped with straps. The shape of them isn’t particularly drag efficient however were originally used on boats where this was not a primary concern and are often still fitted to vessels because that was the type used traditionally.

Pear Shape Anodes

Pear shaped anodes are available in small and larger sizes and in all 3 metal types. They are usually found with 200mm bolt hole centres on straps. Backing pads also available.

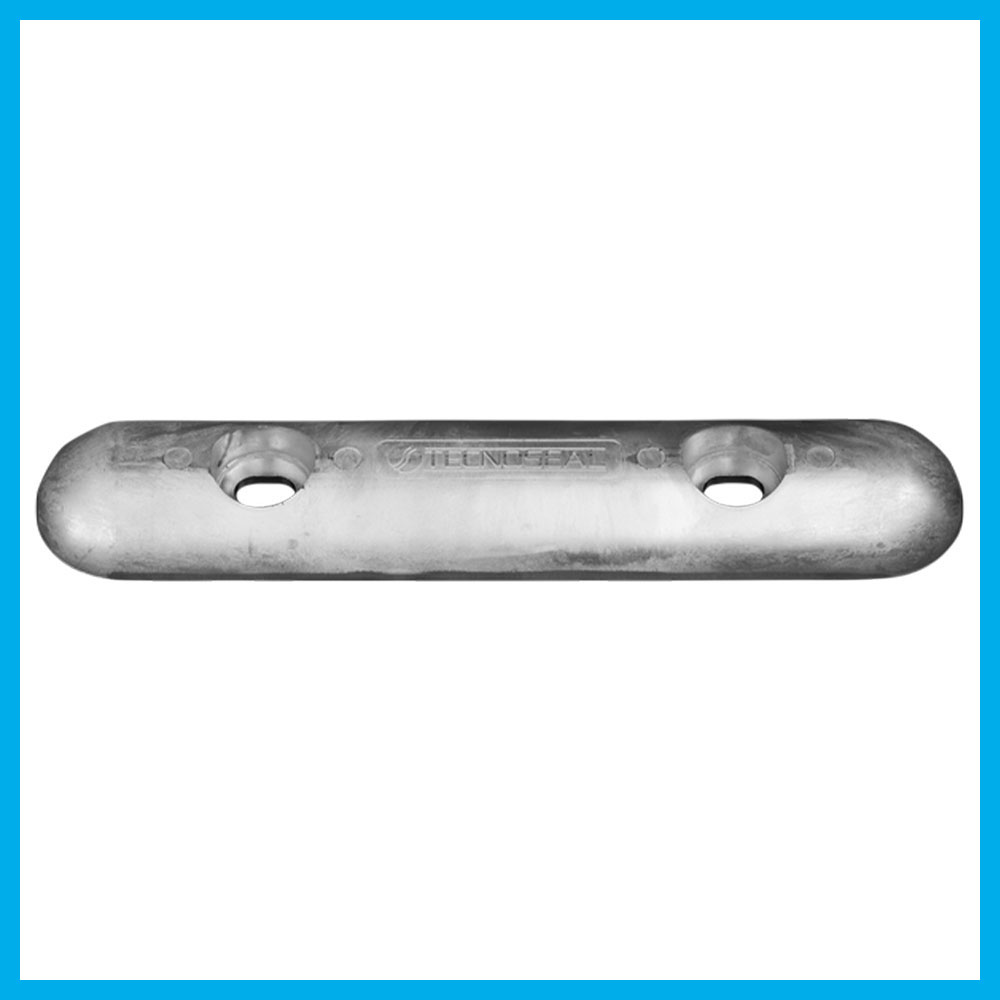

Fairline Type Anodes

The Fairline style anodes are available in all 3 alloys, with backing pads available if they are required. This type has a plate through the centre and comes in 2 sizes with bolt centres at 8 or 9 inches apart. Often used on Fairline boats but also used on others. This is a traditional bar type shape.

Sunseeker Style Anodes

The Sunseeker style anodes are available in zinc, aluminium and magnesium so all water types are covered. These are very large leisure boat anodes, with plate through the centre, and can be fitted to boats where the bolt hole centres are 230mm (approx 9 inches) apart. Backing pads available separately

Vetus Type Anodes

Vetus type anodes with bolt centres at 80mm, 140mm and 200mm apart. Available typically in zinc and aluminium but magnesium available as special order. This type also has an insert plate through the centre for extra durability.